|

| 3 Zone Air Convection. PC Control. 온도 1체넬 온도 profiler |

|

|

|

|

|

상품명

상품명 |

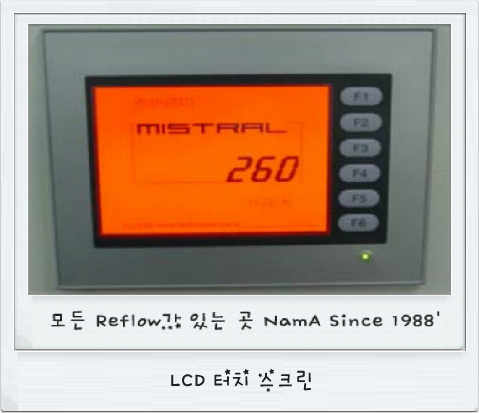

[Reflow-리플로우]

260

1ch x Profiler |

|

|

가격

가격 |

Compact 1.2m . Spring belt type |

|

|

|

|

|

|

|

|

|

|

|

|

|

적용분야 :LED. SMD 부품 신뢰성 적합장비, Small & Medium Reflow작업 공정 및

소규모 작업 공정에서 널리 사용 중.

* 참고 : 생산 Volume이 많으면 360 Model을 추천 드립니다.

end |

|

|

|

|

Full Air Convection

프로화일러 기본. 프린터 for USB Memory

터치 스크린

220V 단상

260 Reflow 장점

|

No Cold Solder Joints |

냉납 및 쇼트 없음 |

|

No Colour Sensitivity |

민감한 변색 없음 |

|

No belt load Sensitivity |

벨트 부하에 변하가 없음 |

|

No Hot Spot |

열에 의한 반점 및 변색 없음 |

|

No Shadowing |

열의 흐름의 사각 지대 없음 |

260 Reflow 은 완벽한 Pb Free 작업 환경이 가능한 장비로서 완벽한 3개의 개별적 Heating Zone 온도 Control이 가능한 Full Air Convection 과 별도의 Cooling Zone으로 구성되어 있다.

장비의 특징 :

- 마이그로 콘트롤에 의한 독립적 제어관리로 누구나 쉽게 장비운영가능.

- 전 Chamber 내 작업공정을 Top Window를 통하여 Monitoring가능.

- 상단 투명 Monitoring창은 고열성 특수 유리로 3단 보온 처리된 디자인.

- 기본 온도 Profiler 기능이 장비 內 있으며 Real Time으로 온도 Graphic 구현.

- Profile측정을 통하여 보다 안정적이고 고-품질의 온도 Profile 운영 가능.

- Full Air Convection방식으로 부품 Device에 손상이 없음.

- 양쪽 수평방향에서 Convection으로 BGA.CSP. Flip Chip 등에 뛰어난 품질

- Converyor Belt 가 Spring Belt로 부품의 흔들림. 수평성이 좋음.

- Power전력은 AC 220 단상으로 일반적 독립 220Volt 콘센트에 사용.

- Bench-Top Oven으로 적은 공간의 Table 위에 사용.

- 배기는 장비 내에 배기 Fan이 있어 작은 거리의 공기 배출 가능.

- 과 전류 및 누전 시 자동 Main전원 차단 안전 기능.

납기 : 1~2주 설치.교육 (장비 재고보유 시)

Forced Air convectionHeat for maximum Temperatures up to 300℃.

Forced Air convection provides uniform heating and prevents shadowing.

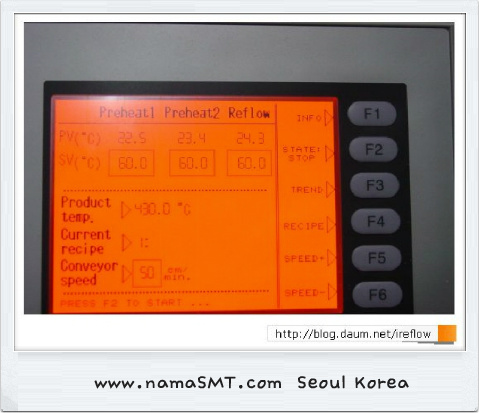

Three heat Zones. each independently controlled for accurate temperature profiles.

Bench-Top unit can be converted to a standalone unit by use of the optional cabinet and also integrated into a fully conveyorized producion line.

Viewing panel allows visual inspection of reflow process.

Detachable thermocouple for measuring substrate temperatures.

|

|

|

|

|

Desk top 사용

▶260 Specification

|

기 능 |

규 격 |

| 1. Heating Zone 및 콘트롤 방식 |

3 Heating zones

Micro-processor controlled Touch Screen LCD

1 x Profiler 기본 내장 |

| 2. Max 온도 및 오차 범위 |

Max 300 ℃ ( 허용 오차 :+.- 1℃) |

| 3. PCB 작업 범위 (폭) |

265mm |

| 4. Heating Chamber 길이 |

860mm |

| 5. Heating Zone |

3 Zone (3개의 완벽분리된 Heating Zone)

준비시간 약 15분 |

| 6. PCB 혹은 부품 통과 높이 |

25mm |

| 7. Conveyor Speed |

10 ~ 60 Cm / Min |

| 8. AC 전원 (220) 1 Phase |

7,800 Watts |

| 9. 배기 공기량 |

160 ㎥/hr |

| 10. Interface |

RS-232C Serial Port |

option |

| 11. 장비유형 |

Bench-Top |

| 12. 무 게 |

60 kg |

| 13. 외 형 (LxWxH) |

1540 x 600 x 360 mm |

| 14. 기타 기능 |

Stainless steel spring wires conveyor or belt

bottom cooling fans at offload Section. |

| 15. Option |

Base Cabinet, RS-232C output | |

|

|

|

|

본 제품은 Desk-Top제품이며, Stand 는 별도 선택사양 임.

1. Stand.

2. Profiler Sensor cable. |

|

|

|