|

SMT장비 [Reflow-리플로우] NR 400 Mesh Conveyor

|

HOME > Products > Reflow > 중소형 리플로우

중소형 리플로우 장비 | NamA Since 1988' HOME > Products > Reflow > 중소형 리플로우

중소형 리플로우 장비 | NamA Since 1988'

|

|

| 4 zone 상/하 별도 온도제어, PC 기본 , PLC제어 방식 |

|

|

|

|

|

상품명

상품명 |

[Reflow-리플로우]

NR 400

Mesh Conveyor |

|

|

가격

가격 |

터치 콘트롤 판넬 4 Zone |

|

|

|

|

|

|

|

|

|

|

|

|

|

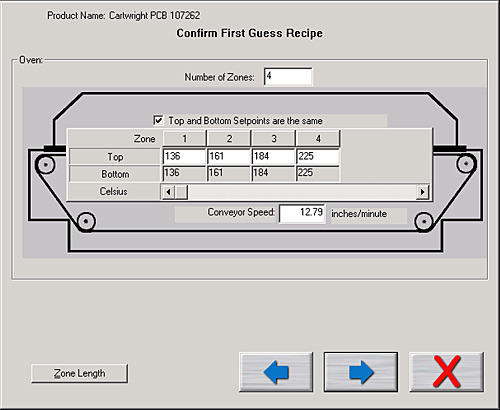

Obtain and Confirm the Oven Settings

Auto-Focus now scans the built-in database for zone temperature/belt speed settings that produce a thermal profile that best fits within the process window when soldering a similarly sized product.

By comparing that profile to the desired process window, Auto-Focus is able to estimate the PWI™ (Process Window Index) a single value that will give the user an indication of how far "within spec" the actual profile will be when using the recommended oven settings.

If the PWI value is acceptable, the user can then obtain the exact temperature settings for each zone along with the belt speed.

|

|

|

|

|

|

|

NR Series Reflow는 47년된 미국의 SMT 전문 판매 업체인 " Manncorp "에서 개발하여

중국 심천 공장 생산하므로 품질. 성능. 경제적인 가격으로 보다 만족을 드리는 Reflow

장비 입니다.

1. 친환경( Eco Friendly)적인 장비로 Flux 필터 시스템이 4 Zone Reflow을 제외하고 기본

으로 장착되어 장비 설치 후 별도 배기의 필터 공조를 하지 않아도 됩니다.

2. "Flux 필터 시스템" 기본으로 구성되어 보다 SOldering 청결도 향상에 기여 및 세척

공정을 절감 시길 수 있습니다.

3. 모든 장비가 “ Full Hot Air Convection”으로 보다 SMD 부품에 손상을 주지 않으며,

고.품질의 Reflow Soldering 구현이 가능 합니다.

4. Mesh. Finger Conveyor 겸용 장비로 Doule Side PCB Reflow Soldering 가능 합니다.

5. NR Relow 장비 Size가 Compact 것이 특징입니다. 적은 공간에 설치 가능 하며 전력

소모 적습니다.

6. Cooling을 "Chiler water" 방식 사용하므로 Cooling Down 온도 변화를 다양하게

구현 가능 합니다.

7. 온도 프로화일러는 세계적으로 유명한 미국의 KIC 온도 Profiler 선택 사용 보다 향상된

고 정밀 Reflow온도 제어 실현이 가능 합니다.

남아전자산업는 미국회사인 Manncorp의 생산 중국공장에서 직접 장비 인도로 보다

보다 빠르고 , 경제적 가격으로 고객에게 장비 공급이 가능 합니다.

|

|

장비유형 |

NR Series 장비는 아래 와 같은 종류가 있습니다. |

|

NR 400 |

4 zone LCD Touch screen / PC 제어 type 2종류,

Mesh 전용 Conveyor.

적용처 : Small Product. SMD 부품제조사. 학교 ,연구소 |

|

NR 500 |

5 zone Flux 필터 unit 기본,

Mesh and Chain Conveyor겸용

적용처 : LED. PCB. FPCB. SMD 부품제조사. 학교 ,연구소 |

|

NR 600 |

6 zone Flux 필터 unit 기본,

Mesh and Chain Conveyor겸용, N2 선택가능

적용처 : 상기 해당 업종 중 , N2가 필요로하는 공정 |

|

NR 800 |

8 zone Flux 필터 unit 기본,

Mesh and Chain Conveyor겸용, N2 선택가능

적용처 : Mass Product 생산을 필요로 하는 업체 |

|

NR 1000 |

10 zone Flux 필터 unit 기본,

Mesh and Chain Conveyor겸용, N2 선택가능

적용처 : 대량생산 및 고 정밀 온도 관리을 필요로하는 공정. |

The NR-400 Series reflow system is a perfect fit for those assemblers who want a compact medium volume lead-free reflow with many of the profiling and performance characteristics of larger ovens.

NR-400 Features

- Four independent topside heat zones with high-mass convection heat sources

- Two lower convection heat zones

- PID temperature control settings to 300°C for lead-free reflow

- 400mm pin conveyor over 500mm stainless steel mesh belt & pin conveyor

- Computer controlled, with password-protected software access

- Three thermocouple inputs for advanced temperature profiling and thermal management functions

- A full-function oven at a space-saving 2000mmlength

- KIC Auto Focus profile prediction software included.

Cost-Efficient Reflow Oven Packs Advanced Features as Standard

Except in the areas of size, energy use and price which are all much lower the NR-4000C reflow oven matches many big ovens, feature for feature, starting with its conveyor system.

NR-400 features a combination stainless steel mesh belt with a board-heating width of 500 mm and an adjustable-width pin conveyor capable of handling assemblies to 400 mm wide. The combination conveyor provides maximum board handling flexibility and ensures double-sided board processing capability. The pin conveyor's automatic oiler is software-driven for optimum preventative maintenance.

Real-Time Temperature Profiling and Profile Prediction Software

Also part of the package is an on-board computer with Windows®-based password-protected software to permit on-screen profiling that, thanks to the included KIC Auto Focus profile prediction software, sets oven parameters automatically.

Process control parameters that produce a specific temperature profile can be saved to and loaded from memory for specific production runs. Once loaded, specific zone temperature settings, upper and lower limits, alarm settings and conveyor speeds can be adjusted as necessary. Password protection separates basic operator functions from critical parameter settings that should only be changed by supervisors or production managers.

Thermal data from up to three separate thermocouple inputs is charted in real-time on-screen.

Reliable Results with Lower Energy Consumption

Reliable, repeatable results are assured with the NR-400 four independently controlled, forced-hot-air convection zones of high mass heating panels and two bottom-side convection zones, spanning a total heating length of 1320 mm.

Three thermocouple inputs are provided for advanced temperature profiling and thermal management functions.

The NR-400 is also a very green machine, consuming just 5 to 8 KW of electricity, even when ramped up to lead-free temperatures of up to 300°C. Timed automatic startup and shutdown functions allow warm-up and cool-down times to be coordinated with breaks in productions and transitions between three separate work shifts in each 24-hour period, promoting both production preparedness and energy savings.

|

|

|

|

|

1. Spec

|

NR-400 T/C T type Touch Pannel , C type PC |

|

1. Lead Free |

Yes |

|

2. Nitrogen Available |

No |

|

3. Mesh Belt Width |

500mm |

|

4. Pin Conveyor |

N/A |

|

5. Conveyor Speed (per min) |

200 ~ 900mm |

|

6. Component Max. Height |

50mm upper |

|

7. Forced Convection |

Yes |

|

8. Number of Heating Zones |

4 Independently Controlled Topside Convection Zones

2 Lower Convection Zones Controlled by Topside

1 Cooling Zone |

|

9. Heated Tunnel Length |

1320 mm |

|

10. Delta T |

±2° C |

|

11. PID* |

Yes |

|

12. Max Temperature |

300° C |

|

13. Ramp Time |

< 15 min |

|

14. Flux Management System |

No |

|

15. Control |

400T =Touch Screen / 400C PC |

|

16. 온도프로화일러 |

Yes |

|

17. Dimensions (L.W.H) |

2000 mm x 1200 mm x 1450 mm |

|

18. Weight |

approx. 1220 kg |

|

19. Power |

3P x 380V+N (220V) + PE, 50/60Hz |

|

20. Required Active Exhaust |

400CFM per port |

|

21. Exhaust Vents |

2 |

|

22. Battery Backup |

UPS Uninterruptible Power Supply for Conveyor & PC |

|

23. Hood Opening Mechanism |

Automatic Raise and Lower |

제품의 긴으 향상을 위하여 예고 없이 사양 변동이 될 수 있습니다.

제품별 자세한 Spec을 참고 하여 주시기 바랍니다.

.jpg)

2. 외형 수치

3 . NR Series Reflow 특징

.jpg)

4 . 특징 및 N2 가능 모델.

.jpg)

|

|

|

|

|

Option

1. N2 (질소) 가능 모델을 확인 하세요.

2. 4 Zone은 Mesh Conveyor 전용이며, 5 zone 이상 Finger . Mesh 겸용 Finger 제거 가능 합니다.

3. Cooling Zone에 급냉 Chiller 선택 시 Cooling Zone이 2개로 1차 2차 Cooling 됩니다.

|

|

|

|

|

|