As higher temperatures and a tighter process window reduce the margin for error in lead-free reflow soldering, Manncorp's revolutionary NR Series reflow can provide many low-, medium- and even high-volume manufacturers a reliable solution to these challenges, especially when factory floorspace and budget are considerations.

Available in either 5, 6, 8, and 10 zone models, CR Series reflow ovens are typically 20%-30% shorter in length than systems with the same number of zones and of comparable throughput, with a lower price tag to match. The key is a proprietary design featuring a combination of high mass heat sources and efficient thermal heat transfer, resulting in uniform heating and exceptional process stability despite varying loads.

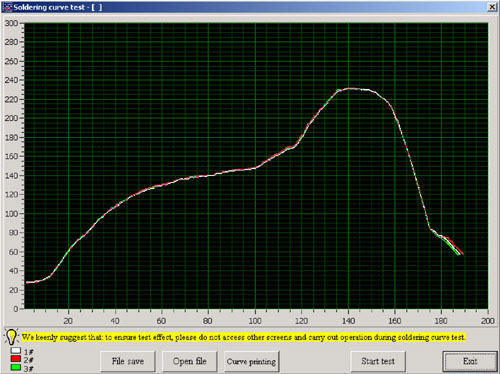

Precise Temperature Profiling

The NR-600 heating zone temperature controllers have an accuracy of ±1°C and, in conjunction with a high-speed blower adjacent to each heat source for maximum convection, ensure a ΔT of ±2°C across the PCB assembly. The system's diffuser design also provides low-velocity, low-turbulence air flow to prevent component shift or disturbance.

Optional thermocouples can be attached at different, critical locations on the PCB, and connect to three built-in inputs (standard) on the oven for communication with NR Series control software and accurate, real-time temperature profiling to match any solder paste manufacturer's specifications.

Included KIC Auto Focus profile prediction software takes the guesswork out of setting up new profiles: simply select your solder paste formula and process window, specify your product's physical characteristics, and Auto Focus returns optimal zone temperature and belt speed settings.

Conveyor Systems

NR-600 is supplied as standard with a combination 570mm stainless-steel mesh belt and adjustable-rail, pin-type conveyor system that handles PCBs up to a maximum of 450 mm.

To eliminate the possibility of jammed or dropped PCB assemblies, all components are constructed of high-quality, high-strength, stainless steel and are built to maintain dimensional tolerances at the high temperatures of lead-free processing.

Advanced automatic chain lubrication and motorized width adjustment are standard features on the pin conveyor. An optional center board support system averts board warpage issues common to larger PCBs processed at higher lead-free temperatures.

Conveyor speed is programmable from 400 ~1800mm per minute to accommodate any production requirement.

N2 Atmosphere Compatible LF Reduced Oxidation

While the debate over air or inert reflow atmospheres continues, Manncorp, as an option, offers the NR-600 in a nitrogen compatible configuration for manufacturers who want the flexibility for soldering in both environments.

Most experts agree that the reduction of oxygen through the introduction of an inert gas usually N2 will allow a wider process window and provide better solder joints through reduced oxidation. The enhanced flow design of the heating chamber in the NR-600 nitrogen-configured system lends itself to efficient heat transfer and ensures low nitrogen consumption while maintaining O2 levels between 300-1000 ppm.

Cooling Rates Required By Some LF Solders

Because the higher liquidous temperatures required by lead-free solders approach the limits of many SMT components and PCB assemblies, more aggressive cooling is often required to reduce peak temperature exposure times. Some recent studies also indicate that cooling rates have a significant effect on solder joint grain structure.

For these reasons, an internal water-chilled recirculating cooling system option is available for the NR-600 model and allows users to alter cooling rates to meet solder paste manufacturers recommendations to a much greater degree than is possible with the exclusive use of the standard air cooling system.

%20사본.jpg)

Advanced Functionality and Process Management Capability

Operation and control of all NR Series reflow systems is accomplished through an attractive, uncluttered user interface that features a full-screen, virtual view of the system with display of pre-set and actual zone temperatures, system status and conveyor speed.

The Windows-based oven management software includes advanced functions for temperature profiling, timed automatic startup and shutdown, audible and visual alarms, and password protection.

A PC-controller with 15" flat screen monitor, keyboard and trackball allows unlimited storage and networking capability.

All systems employ UPS battery backup to ensure removal of all product from the oven in the event of a power outage.